Using the PhotonClean laser cleaning machines makes cleaning easy!

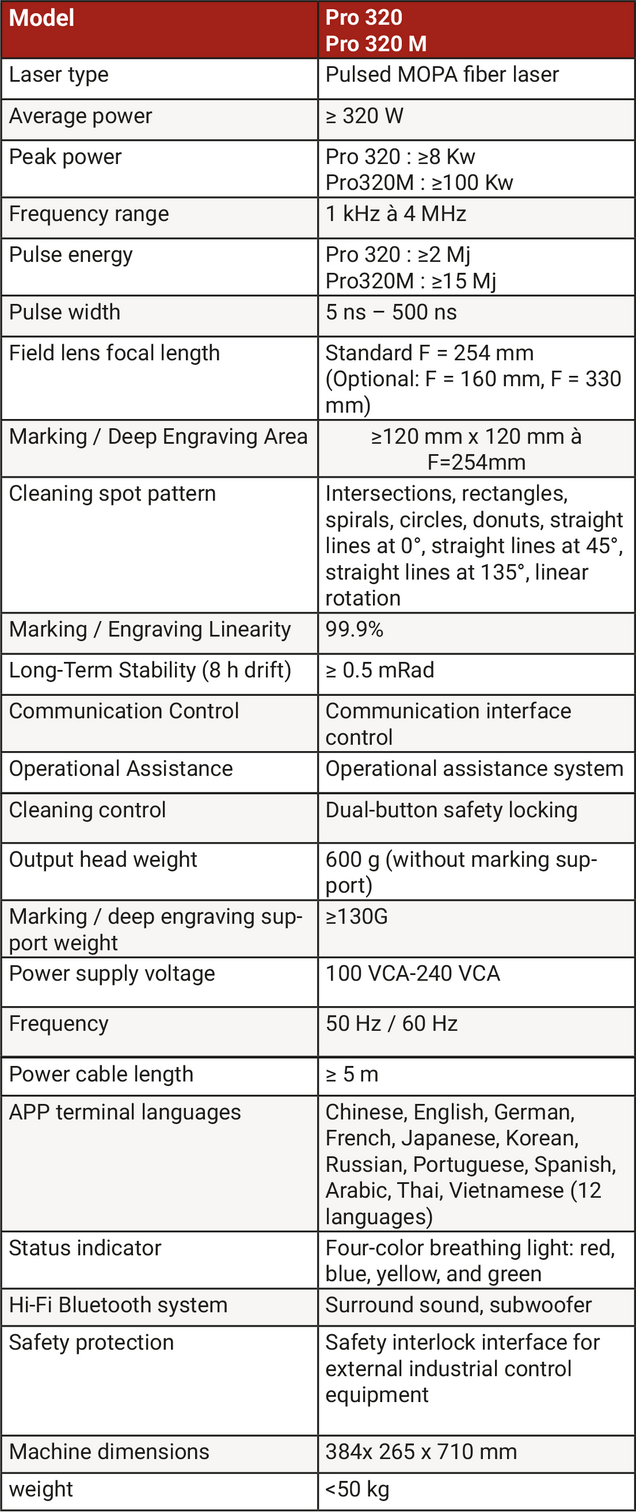

Our laser cleaning machine combines powerful laser technology and user-friendly control to clean various material surfaces efficiently. The devices are designed to be compact and durable, capable of removing rust, paint, and pollutants without damaging the substrate, making them particularly suitable for industrial, automotive, and maintenance fields.

Cleaning

Laser engraving delivers a premium, precise, and permanent marking solution, ideal for enhancing your parts and ensuring long-lasting identification. With no contact and no consumables, it provides a clean, elegant, and professional finish on a wide range of materials.

Graving

Laser engraving delivers a premium, precise, and permanent marking solution, ideal for enhancing your parts and ensuring long-lasting identification. With no contact and no consumables, it provides a clean, elegant, and professional finish on a wide range of materials.

Marking

The Cleaner 320M features a precise and versatile laser marking function, ideal for industrial identification and part customization. It delivers clean, sharp, and long-lasting markings, such as logos, text, serial numbers, and codes, directly on surfaces, without contact or consumables.

Laser cleaning in detail

The success of laser cleaning can be attributed to the numerous advantages of the process.

Laser beam cleaning is a method that, for quite some time now, is no longer solely implemented for mold cleaning, but that can also be implemented to clean a wide range of different components during processing. The success of laser cleaning as an alternative to conventional cleaning methods can be attributed to the numerous advantages of the process. For one, the method only incurs very low operating costs, since no cleaning agents are used and no waste disposal is required. Secondly, the process is very precise and gentle on surfaces. Finally, the excellent cleaning results that can be achieved with the laser beam are ultimately the decisive factor. The laser evaporates oxides, dirt particles of all kinds and above all impurities from polymer-based lubricants, which are particularly difficult to remove, in a matter of seconds. The remaining surface is perfectly prepared for subsequent machining, e.g. laser welding.